Electric Bus Battery Management for PTO: Key Insights from UITP Training

Operating, Maintenance and Asset Management of E-Buses and their Batteries

The UITP Academy training on electric bus battery management focused on helping public transport operators improve battery performance, extend lifespan, and reduce costs. The transition to electric fleets presents new challenges, and managing battery health, predictive maintenance, and fleet efficiency is essential. volytica diagnostics shared expertise on battery state of health (SoH), limitations of BMS data, and independent diagnostics.

Real-time monitoring and predictive analytics can unlock hidden potential and ensure safer, more cost-effective operations.

This training took place from February 4 to 13, 2025, as part of UITP Academy’s initiative to support the electrification of public transport worldwide.

Adrian Poher, Senior Manager Events at UITP, highlighted the significance of this initiative: “The Battery Management training is a brand-new initiative for UITP and its members!

We’re thrilled to have volytica on board for the initial sessions, setting the foundation for a deep understanding of battery management.”

Key Takeaways from the Training

volytica diagnostics was honored to contribute as an expert, sharing practical insights on optimizing battery performance. Some of the most important learnings included:

→ Most batteries are not used to their full potential.

Monitoring and predictive analytics can unlock significant efficiency improvements.

→ Battery degradation is complex.

It depends on multiple factors, including usage patterns, stress levels, and battery chemistry.

→ BMS is the “brain” of the battery but has limitations.

It primarily ensures safety but does not optimize long-term performance.

→ Balancing and stress reduction are crucial.

Battery management strategies can significantly extend battery lifespan and reduce operational risks.

Claudius Jehle, CEO of volytica diagnostics, emphasized the growing importance of battery health:

“Battery health in electric buses has become such an important issue that even UITP – the global association of public transport stakeholders – has dedicated an entire webinar series to it. This reflects how deeply the issue has reached the minds of its members. However, many still underestimate the complexity: accurately assessing the state of health (SoH) and understanding long-term battery performance isn’t possible without expert knowledge. As fleets grow and age, reliable diagnostics will be key to ensuring the safety, efficiency, and cost-effectiveness of public transportation.”

Battery Management Challenges

The sessions were highly interactive, with participants engaging in discussions on battery management challenges. Some of the most debated topics included:

→ Limitations of OEM-defined SoH values:

Do manufacturer-provided SoH values truly reflect a battery’s actual condition? Many operators called for independent diagnostics.

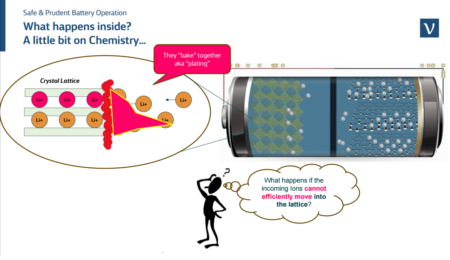

→ The impact of charging practices on battery lifespan:

How do high C-rates and continuous charging contribute to lithium plating and accelerated degradation?

→ Differences in balancing strategies:

Battery manufacturers use different approaches, which can have a significant impact on long-term performance.

→ Second-life applications and residual battery value:

How can operators maximize the value of their batteries beyond their first life cycle?

Highlights from the Attendees’ Discussions on Battery Health and Performance

Some of the most insightful discussions revolved around:

- The limitations of standard SoH definitions and how alternative diagnostics can provide a more accurate picture of battery health.

- The role of charging practices in battery lifespan, including the impact of high C-rates and continuous charging on lithium plating.

- The differences in balancing strategies among battery manufacturers and how these affect long-term battery performance.

- The potential for independent SoH estimations to challenge OEM claims and ensure transparency in battery performance evaluations.

Looking for Expert Talks on Battery Analytics?

The UITP Academy training reinforced the importance of data-driven battery management for electric bus operators and fleet managers.

Are you looking for expert insights on battery analytics, predictive maintenance, or fleet optimization?

Our specialists are available as speakers, consultants, and trainers, offering in-depth knowledge on batteries, cell chemistry, aging, algorithms, and data-driven operational strategies.

📩 Get in touch at marketing@volytica.com – we look forward to sharing our expertise!

Collected Questions & Answers from UITP Battery Training

Battery Basics & State of Health (SoH)

Q: Does volytica work in real time or does it only diagnose SoH?

A: We do both: real-time monitoring and battery diagnostics including SoH. We track common battery KPIs such as SoH, degradation and anomalies, as well as proprietary metrics such as vdx stresslevel®. This enables advanced tracking, anomaly detection, alert thresholds and recommended actions. Customers can also choose from basic battery insights or one-time assessments, such as post-event historical data analysis or post-warranty or resale value assessments.

Q: Can we, the user/operator, measure the SoH manually?

A: Measuring SoH manually is challenging and often inaccurate. A reliable estimate requires continuous tracking of key parameters such as charge cycles, temperature, and power dissipation. Our algorithms provide accurate, real-time SoH assessment by continuously tracking these factors over time.

Q: Does SoH definition include malfunctions of some cells?

A: Standard SoH definitions typically do not account for individual cell malfunctions. Our algorithms offer more granular diagnostics, enabling the detection of cell-level issues and hidden performance problems that are not reflected in standard SoH metrics.

Q: Would the SoH estimated by volytica diagnostics be used to challenge OEM SoH claims?

A: Yes, independent diagnostics such as ours can provide a more transparent assessment of battery health compared to OEM defined SoH values that may serve marketing interests.

Battery Management & Performance Optimization

Q: What parameters affect battery stress?

A: Battery stress is affected by several factors, including

- Temperature variations

- Depth of discharge (DoD)

- Charge and discharge rates (C-rate)

- Operating conditions (idle time vs. active use)

- Our algorithms track these factors to detect stress early and optimize performance for longer, more efficient operation.

Q: Why do some manufacturers balance at the top of the SoC and others at the bottom?

A: Balancing strategies vary based on battery chemistry and system objectives. Some prioritize balancing the top SoC to avoid overcharging, while others focus on the bottom SoC to extend battery life.

Our system evaluates and provides insight into the most efficient strategy based on real-time data and system requirements.

Q: Can the BMS re-balance a low cell?

A: BMS systems use passive or active balancing, but their effectiveness varies. Our algorithms can detect imbalances early and provide insight into corrective actions, helping to prevent long-term performance issues.

Battery Safety & Longevity

Q: Is SoH a good safety indicator?

A: No, a low SoH does not necessarily mean that a battery is unsafe. Some degraded batteries may still operate safely, while others with high SoH may pose risks due to hidden defects such as lithium plating.

Q: Does keeping a charger plugged in help manage battery internal temperature?

A: Yes, leaving the charger plugged in can help stabilize battery temperature, especially in cold environments.

Q: What is the best indicator that a battery is imbalanced/ out of balance?

A: Our volytica KPI SOBC® (State of Balance Charge) is a key metric for detecting imbalance. Ideally the SOBC should be close to 1.

Procurement & Best Practices

Q: What should buyers ask OEMs before purchasing batteries?

A: Purchasers should request detailed SoH definitions, degradation data, operational recommendations and stress level assessments to ensure long-term battery reliability.

Q: Is it safe for vehicle manufacturers to use third party battery cells with their own BMS?

A: This depends on the quality of the integration. A mismatch between BMS algorithms and battery chemistry can lead to inaccurate monitoring and increased safety risks.