Sodium-Ion Batteries: The Next Big Wave in Stationary Energy Storage?

While the ‘battery tsunami’ is about to reach Europe (cf. Der Spiegel), the next big wave is already waiting in the wings. Sodium-ion batteries, once considered a niche alternative to lithium-ion technology, are rapidly gaining traction as a sustainable, scalable, and cost-effective solution for stationary energy storage. As we stand at this turning point, it’s crucial to explore the potential of this technology, its suitability for stationary applications, and Europe’s role in driving its development.

The Potential of Sodium-Ion Batteries: A Game-Changer in Energy Storage

Lithium-ion batteries have dominated the energy storage market for decades and will be the most prominent storage solution in the upcoming years. However, their reliance on scarce and geographically concentrated resources like lithium and cobalt presents significant challenges. Enter sodium-ion batteries: leveraging sodium, a material that is abundant, widely distributed, and inexpensive, promise to address some of the most pressing supply chain issues facing the energy sector today.

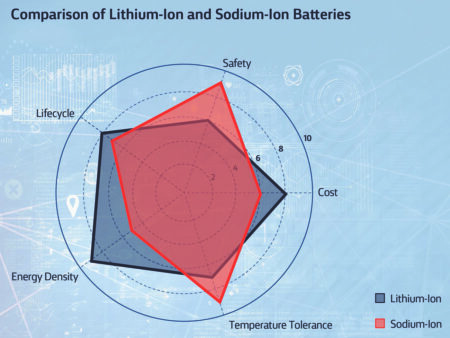

Recent advancements in sodium-ion battery chemistry have drastically improved their energy density, cycle life, and safety. While they still trail lithium-ion batteries in specific energy, these improvements make them theoretically well-suited for stationary energy storage, where cost, resource availability, and safety often take precedence over energy-to-weight ratios.

Market Readiness: Navigating the Path to Commercial Viability

While the promise of sodium-ion batteries is undeniable, their market readiness is accelerating rapidly. Several companies and recent developments showcase the growing confidence in sodium-ion technology:

- CATL has unveiled sodium-ion battery prototypes with improved energy densities exceeding 200 Wh/kg, aimed at both stationary storage and EV applications. Mass production is slated for 2025.

- BYD continues to advance sodium-ion production, targeting price parity with lithium iron phosphate batteries. They are investing in production facilities with multi-gigawatt-hour annual capacities.

- U.S.-based Acculon Energy commenced sodium-ion battery production in 2024, scaling toward 2 GWh capacity.

- Natron Energy has begun sodium-ion production focused on stationary storage, with ambitious gigafactory plans for expanded capacity.

Why Sodium-Ion is Perfect for Stationary Applications

Stationary energy storage systems (ESS) represent an ideal use case for sodium-ion technology. Unlike electric vehicles, where energy density and weight are critical factors, stationary applications prioritize other metrics, such as:

- Cost-Effectiveness: Sodium-ion batteries are theoretically cost-effective due to their reliance on abundant materials like sodium (cheaper than lithium) and aluminum (less expensive than copper). However, at the system level, cost advantages depend on achieving economies of scale and optimized manufacturing processes, which are yet to be realized in large-scale deployments.

- Safety: Sodium-ion batteries are inherently safer due to lower risks of thermal runaway compared to lithium-ion counterparts. However, while laboratory tests demonstrate superior safety profiles, large-scale system deployments must address potential risks arising from new chemistries and failure modes that could emerge under practical conditions.

- Longevity: Sodium-ion batteries show enhanced cycle life in laboratory environments, suggesting they can perform consistently over extended periods. Validating this longevity in real-world, large-scale systems are crucial, as factors like operational stress and environmental variability may impact performance.

- Temperature Tolerance: Sodium-ion batteries function effectively across a broader temperature range, reducing reliance on expensive cooling systems. Yet, field tests are needed to confirm how temperature fluctuations in diverse geographies impact their efficiency and lifecycle over time.

The transition from laboratory results to commercial reality will involve addressing challenges such as manufacturing scalability, supply chain optimization, and integration with existing energy systems.

Europe’s Role in Sodium-Ion Battery Development

While China has emerged as a dominant player in the commercialization of sodium-ion batteries, driving large-scale production and export initiatives, Europe holds significant possibilities to capture a substantial share of the global market. Europe’s advanced industrial ecosystem, technical expertise, and commitment to sustainability provide a unique foundation to scale sodium-ion technologies. With strategic investments in infrastructure and innovation, Europe could position itself not only as a leader in research and development but also as a major manufacturer and exporter of sodium-ion systems.

Particularly, Europe can become the leading developer of sophisticated battery analytics and monitoring systems, which is key to maximizing the performance, safety, and longevity of sodium-ion batteries in large-scale applications. By leveraging real-time data and diagnostics, these solutions can ensure that sodium-ion batteries reach their full potential while addressing challenges such as degradation and performance variability.

If these efforts are matched with policies and incentives to boost production and attract international investments, Europe can transform its role from an innovator to a key global supplier in the sodium-ion battery industry.

Our Contribution to the Sodium-Ion Transition

At volytica diagnostics, we are committed to enabling the sodium-ion revolution through advanced monitoring solutions. Leveraging years of expertise with lithium-ion technologies, our agnostic platforms are ready to support the needs of sodium-ion systems. Our capabilities include:

- Real-Time Monitoring: Delivering actionable data on battery health, anomalies, and performance metrics.

- Lifecycle Management: Optimizing battery longevity while minimizing maintenance costs.

- Safety Assurance: Identifying and mitigating potential risks before they impact operations.

- Factory and Site Acceptance Testing (FAT/SAT): Minimizing risks during deployment, ensure compliance with performance benchmarks, and enhance the overall success of sodium-ion battery installations.

Turning Potential into Reality

The road ahead for sodium-ion technology is filled with opportunity but requires a collective effort. Industry collaboration, strategic investments, and advanced technologies will be instrumental in scaling this promising energy storage solution.

What About You? Let’s Talk Sodium-Ion Projects

Are you exploring sodium-ion battery technologies for your next energy storage project? Whether you need monitoring expertise or want to partner with experienced battery experts, we are here to support your goals. Contact us to learn more about our solutions and how we can empower your journey in sodium-ion technology.

About the Author

Senior Battery Expert and Analyst

Christian Heubner is a Senior Battery Expert at volytica diagnostics GmbH, a company focused on independent battery quality and health diagnostics. Christian studied Chemical Engineering at the TU Dresden and completed his PhD about local heat generation in Lithium-ion batteries at the Fraunhofer Institute for Ceramic Technologies and Systems in 2016. Afterwards Christian worked as a team leader on battery related topics spanning from materials development over characterization techniques to battery production. He authored 80 peer-review publications and gives lectures on battery fundamentals and future trends in the battery landscape.